Soudal’s comprehensive range of trade silicones will now be filled right here in Australia thanks to a multimillion-dollar investment designed to cut shipping times, improve agility and enhance product quality.

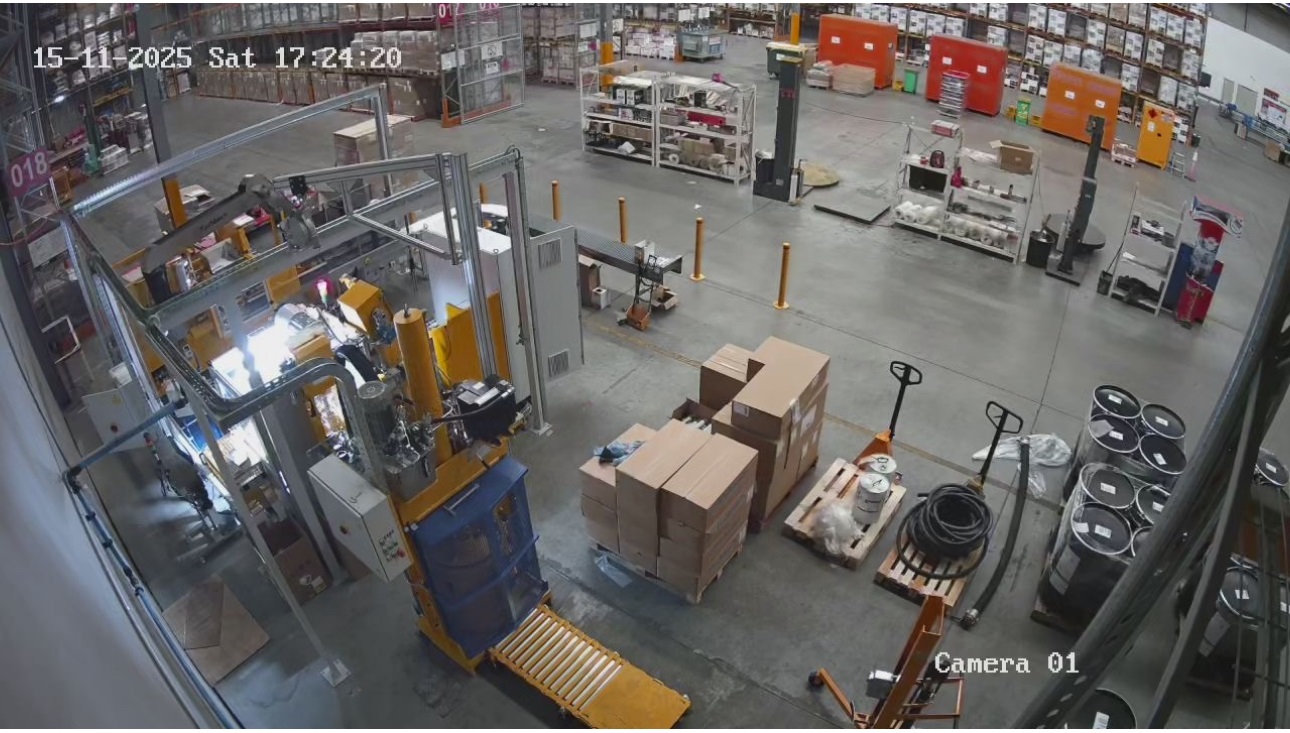

A new filling line was commissioned in Western Sydney in November and expansion plans are already in place, creating a strong and climate-friendly manufacturing affiliate hub that will service the entire Pacific region.

Lead times will reduce from three months to just days or weeks, and Soudal Australia can now custom fill ‘private label’ cartridges for clients who wish to sell premium silicone products under their own brand.

“This new filling line is a fundamental building block for Soudal to better service Australia, New Zealand and other Pacific nations,” explains Soudal Australia’s Country Manager, David Grace. “We are laying the platform for future growth, and this is just one of many filling lines coming to our Australian operation. It’s an exciting time for Soudal and with this significant investment, a strong signal is being sent that Australia and the Pacific region is a future focus point for the business.”

After nearly six decades in business, Soudal aims to become the world’s largest independent manufacturer and service-oriented supplier of silicones, adhesives and PU foams. Our ambition to grow has seen us become the main challenger to the big players in markets all over the world, including Australasia.

Most Soudal products are currently imported from Europe. But upgrading our Australian distribution and sales hub to include manufacturing will substantially improve efficiency, quality and sustainability.

Customers will have access to fresher stock with a full shelf life, and won’t be reliant on overseas supply chains which are exposed to risks such as trade restrictions, tariffs, political instability, strikes, natural disasters and other disruptions like Covid.

“Not only are we now more responsive – with the capability to provide our trusted Soudal branded range of silicones locally – we have the agility to provide ‘private label’ cartridges for clients who wish to sell premium silicone products under their own brand”. David says.

Soudal’s carbon footprint will reduce significantly by eliminating long-haul shipping, and the new filling line is powered entirely by solar power. Around 90% of consumables used during production will also be recycled as we work towards our global goal of being climate neutral by 2050.

Filling in Australia has kicked off with our Pro Roof & Gutter (Clear) which will soon be followed by Bathroom & Kitchen, Glass & Glazing, and Soudal’s highly-regarded Pureseal range of silicones.

Soudal Australia’s Head of Operations, Jozsef Berta, says the project has been two years in the making. The new equipment was purchased from Germany and assembled at Soudal’s headquarters in Belgium before being shipped out to Australia.

“It’s capable of filling over two million cartridges per annum while running a standard shift. It has significant output capabilities and we immediately produced 20,000 units in the week and a half we were training our local team. The project was delivered on time, and our local sales team can now flourish.”

Jozsef says all silicone products will be made to Soudal’s strict European standards and quality control testing is carried out continuously, with remote technical support available 24/7 from Belgium.

“Our silicones will be made in Australia with local know-how, accountability and pride, to meet the highest European standards which is rare. We can now respond faster to customer needs than ever before and grow Soudal’s presence and market share throughout the Pacific region.”