Adhesive failure is a common issue that builders, manufacturers, and DIY enthusiasts face. Adhesives are essential for a range of applications, but when they fail, the results can be costly and time-consuming. To prevent adhesive failure, it’s important to understand the various causes, the types of failure, and how to avoid them.

This guide breaks down the causes of adhesive failure, explores the differences between adhesive and cohesive failure, and provides practical tips to help prevent these problems.

Key Takeaways about Adhesive Failures

- There are three main types of adhesive failure: adhesive failure, cohesive failure, and substrate failure.

- The common causes of adhesive failure include incorrect adhesive selection, improper preparation, poor surface cleaning, material design changes, plasticiser migration, curing issues, and environmental factors.

- To prevent failure and achieve long-lasting bonds, always choose the right adhesive for the material and conditions, ensure proper surface preparation, control curing conditions, and follow the manufacturer’s instructions.

What are the Types of Adhesive Failure?

There are three main types of adhesive failure: adhesive failure, cohesive failure, and substrate failure. Each type has its own set of causes and symptoms, which we will cover below.

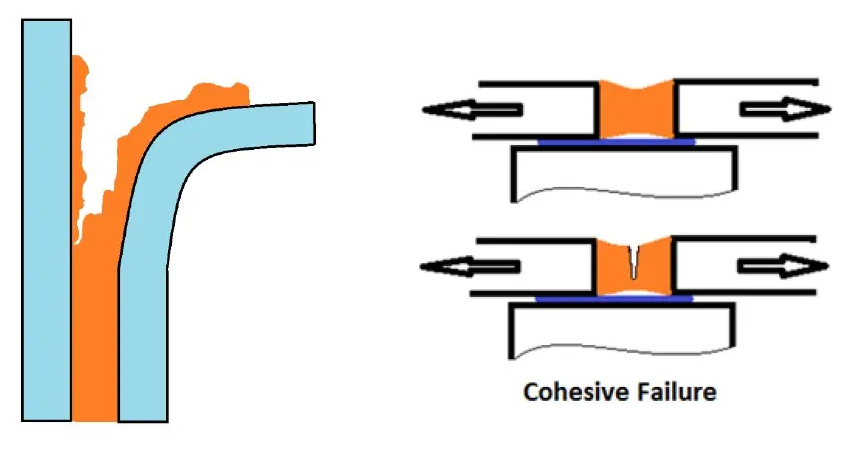

1. Cohesive Failure (Cohesive Fracture)

Cohesive failure occurs when the adhesive breaks apart within itself, meaning the bond within the adhesive is weaker than the bond between the adhesive and the substrate. This type of failure is often preferable to adhesive failure since it indicates that the adhesive adhered well to the substrate.

Causes of Cohesive Failure

- Curing defects: If the adhesive cures improperly (e.g., from uneven temperature or movement during curing), it can cause cohesive fracture.

- Defects in adhesive: Issues like air bubbles or contamination can lead to cohesive failure.

- Ageing: Over time, the adhesive may degrade, leading to cohesive fracture.

- Substrate movement: If the movement of the substrates exceeds the joint design, it may cause cohesive failure.

What Cohesive Failure Looks Like

The adhesive will break within itself, with the bond to the substrate remaining intact. The failure occurs in the adhesive material rather than the bond to the substrate.

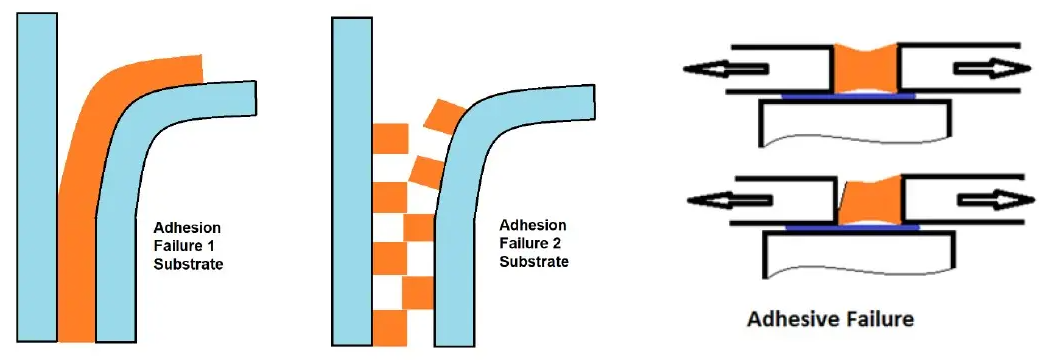

2. Adhesive Failure (vs Cohesive Failure)

Adhesive failure occurs when the adhesive separates from the substrate it was meant to bond to. This is a more severe issue compared to cohesive failure, as it means the bond to the substrate is weaker than the internal structure of the adhesive itself.

Causes of Adhesive Failure

- Improper substrate preparation: Failure to clean or prepare the surface correctly can cause the adhesive to fail to bond properly.

- Incorrect adhesive choice: Using the wrong adhesive for the substrate can lead to adhesive failure.

- Expired adhesive: Using adhesives past their “Best Before” date can prevent proper bonding.

- Environmental conditions: High moisture, temperature variations, or other environmental factors can negatively affect adhesive performance, leading to adhesive failure.

What Adhesive Failure Looks Like

The adhesive separates from the substrate, either partially or fully, and you may notice a gap between the adhesive and the surface.

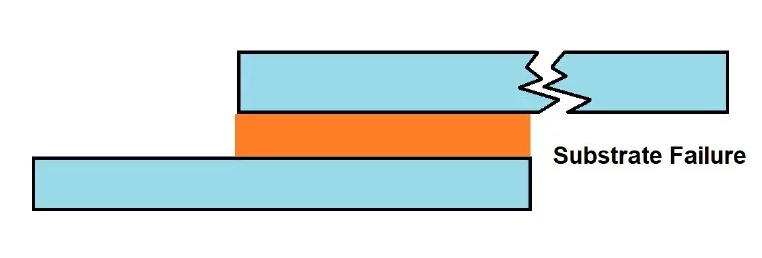

3. Substrate Failure

Substrate failure occurs when the material being bonded is weaker than the adhesive itself, causing the substrate to break rather than the adhesive bond. This is not an adhesive problem but a material issue, meaning the substrate couldn’t withstand the bond.

Causes of Substrate Failure

- Weak substrate material: The substrate may not have the strength to handle the adhesive bond.

- Chemical or physical damage: Exposure to environmental elements, like chemicals or physical stress, can degrade the substrate over time.

- Ageing of the substrate: As substrates age, they may deteriorate, making them prone to failure under the adhesive bond.

What Substrate Failure Looks Like

The adhesive bond stays intact, but the substrate itself fractures or breaks, indicating that the material wasn’t strong enough to support the adhesive.

Seven Common Causes of Adhesive Failure

1. Incorrect Adhesive Selection

Choosing the right adhesive for the material you’re working with is critical. Adhesive failure often occurs when the wrong adhesive is used for a particular substrate or project type. Always select an adhesive that’s designed for the specific application such as specially designed tile adhesives, timber floor adhesives, and many more.

2. Improper Adhesive Preparation

Not preparing the adhesive or substrate properly can lead to bonding problems. Follow the manufacturer’s instructions on preparation methods and curing times to avoid adhesive failure. Proper surface cleaning and priming are essential for good adhesion.

3. Poor Surface Cleaning

Surface contamination, such as dust, oil, or dirt, can prevent adhesives from bonding correctly. Always ensure the surface is cleaned thoroughly before applying adhesive to prevent adhesive failure.

4. Material Design Changes

Changes in material production or design can affect the adhesion properties. Even if the material still meets performance standards, it might be less compatible with the adhesive, leading to adhesive failure. Pay attention to material changes and always clean the surface thoroughly.

5. Plasticiser Migration

Some plastics contain plasticisers that can migrate to the surface over time, interfering with the adhesive’s curing process. This migration can lead to adhesive and cohesive failure. When selecting an adhesive, ensure it’s compatible with the substrate to avoid issues with plasticiser migration.

6. Cure Time and Temperature

Adhesives have specific curing temperature and time requirements. Cure time and temperature play a major role in the success of the bond. Too high or too low a temperature can cause the adhesive to degrade or fail to cure properly.

7. Environmental Conditions

Environmental factors, such as humidity, temperature, and exposure to chemicals, can negatively impact the performance of adhesives. Too much moisture or incorrect temperature can cause adhesion failure in coating or other issues related to adhesive failure.

Key Tips to Preventing Adhesive Failures

To avoid adhesive failure types and ensure a reliable, long-lasting bond, follow these tips:

- Choose the right adhesive: Make sure the adhesive is compatible with both the substrate and the environmental conditions.

- Properly prepare the surface: Clean the substrate to remove any dust, oil, or dirt and use adhesion promoters to prime the surface.

- Control environmental factors: Apply adhesives in environments that meet the manufacturer’s recommended temperature and humidity levels. Depending on your needs, select adhesives with high heat resistance or those designed for waterproofing.

- Follow product instructions: Always adhere to the manufacturer’s guidelines for adhesive preparation, curing, and application.

Final Thoughts: Preventing Adhesive Failure for a Stronger Bond

Understanding the root causes of adhesive failure, including adhesive and cohesive failure, and substrate failure, is essential for achieving durable, long-lasting bonds. By carefully selecting the right adhesive, following proper surface preparation, and considering environmental factors, you can avoid adhesive failure types and ensure successful bonding on your projects.

Explore our range of reliable industrial adhesives, adhesive sealants, and accessories for your next DIY project or trade job.

FAQs About Adhesive Failure

What’s the difference between adhesive failure and cohesive failure?

Adhesive failure happens when the adhesive separates from the substrate, while cohesive failure occurs when the adhesive breaks within itself. Both failures indicate different issues, with adhesive failure usually being more critical as it involves the adhesive bond to the substrate. For a more durable bond, be sure to use the correct adhesive for your specific substrate.

What are the most common causes of adhesive failure?

The most common causes include incorrect adhesive selection, improper surface preparation, environmental factors, and curing issues. Ensure you follow product instructions and choose the correct adhesive product for your specific needs to avoid adhesive failure.

What causes substrate failure in adhesive bonding?

Substrate failure occurs when the material being bonded is weaker than the adhesive itself, causing the substrate to fracture. This is usually due to the substrate being undersized or damaged, not the adhesive.

How do I prevent adhesion failure in coating?

Adhesion failure in coating can occur when the surface isn’t properly prepped or when the wrong adhesive is used. To avoid this, use an effective surface activator to ensure the surface is clean, dry, and free of contaminants, and choose the right adhesive designed for coatings.